CNC machining company in usa Applications in Aerospace & Robotics

CNC machining company in usa has become a cornerstone of modern manufacturing, driving innovation across multiple industries, particularly aerospace, robotics, and automotive sectors in the USA. With the precision, efficiency, and flexibility CNC machines offer, they are revolutionizing the design and production of components that meet the highest standards. This article explores how CNC machining applications are transforming the aerospace, robotics, and automotive industries, enabling advancements in technology and performance.

CNC Machining in the Aerospace Industry

The aerospace sector demands precision and reliability in every component, as even the smallest error can have severe consequences. CNC machining provides the high precision and repeatability necessary for manufacturing parts used in aircraft and spacecraft, ensuring safety and performance.

Precision Components for Aircraft and Satellites

Top CNC machining in usa plays a pivotal role in producing the intricate and high-tolerance parts required for aircraft and satellite systems. Components like engine parts, turbine blades, and structural elements demand precise measurements and flawless finishes. With CNC machining, aerospace manufacturers in the USA can achieve the accuracy required to meet these exacting standards, contributing to the safety and longevity of aviation and space exploration.

Lightweight Parts for Aerospace Efficiency

As the aerospace industry shifts towards more fuel-efficient designs, lightweight materials are increasingly being used in aircraft. CNC machining allows for the efficient processing of materials such as titanium and aluminum alloys, which are critical for reducing weight without compromising strength. These advancements help manufacturers create components that improve fuel efficiency and reduce emissions, aligning with the industry’s sustainability goals.

CNC Machining in Robotics

Robotics is another industry that has greatly benefited from CNC machining. Robots rely on precision-engineered parts to perform tasks with speed and accuracy. CNC machining allows manufacturers to create these parts with high precision, enhancing the functionality and efficiency of robotic systems.

High-Precision Parts for Robotic Arms

In robotics, particularly for manufacturing and automation, robotic arms require highly precise and durable parts to function effectively. CNC machining is ideal for producing these components, including joints, gears, and actuators, which must be manufactured with exact specifications. These precision components ensure that robots can perform repetitive tasks with high accuracy, contributing to increased productivity in industries like electronics, medical devices, and consumer goods.

Custom Components for Specialized Robotics Applications

CNC machining also enables the creation of custom components for specialized robotics applications, such as surgical robots or drones. These systems require highly customized parts to meet unique performance criteria. CNC technology allows for rapid prototyping and production of custom parts, making it an invaluable tool in the robotics sector, where adaptability and precision are essential.

CNC Machining in the Automotive Industry

The automotive industry has long relied on CNC machining to produce parts with precision and efficiency. As vehicles become more technologically advanced, CNC machining company in usa is helping automotive manufacturers meet the growing demand for high-performance, lightweight, and durable components.

Precision Engine and Transmission Components

In automotive manufacturing, engine and transmission components must meet strict quality standards to ensure reliability and performance. CNC machining allows for the production of high-tolerance engine blocks, pistons, crankshafts, and gear systems that operate seamlessly under intense conditions. By maintaining tight tolerances, CNC machining ensures that these critical components contribute to the vehicle’s overall performance and longevity.

Lightweight Materials for Fuel Efficiency

With the automotive industry increasingly focused on sustainability, reducing vehicle weight is a key strategy for improving fuel efficiency. CNC machining enables the precise manufacturing of lightweight materials, including carbon fiber, aluminum, and advanced polymers. By producing these materials with high accuracy, CNC machining helps automotive manufacturers create components that reduce overall vehicle weight without compromising safety or performance.

Technological Advancements in CNC Machining

The evolution of CNC machining technology continues to enhance its capabilities, enabling manufacturers to achieve even higher levels of precision, speed, and efficiency. Innovations such as multi-axis machining and additive manufacturing integration are transforming the way parts are produced across all sectors.

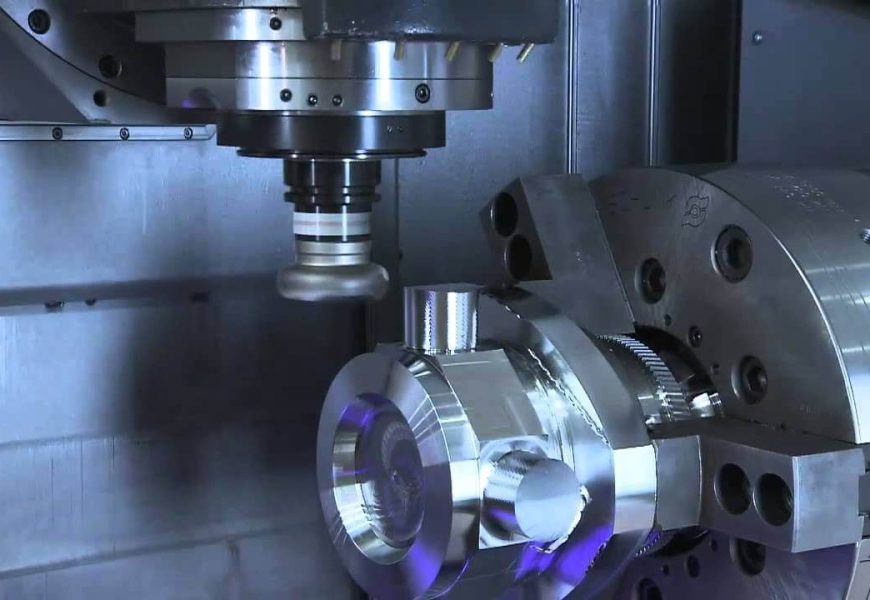

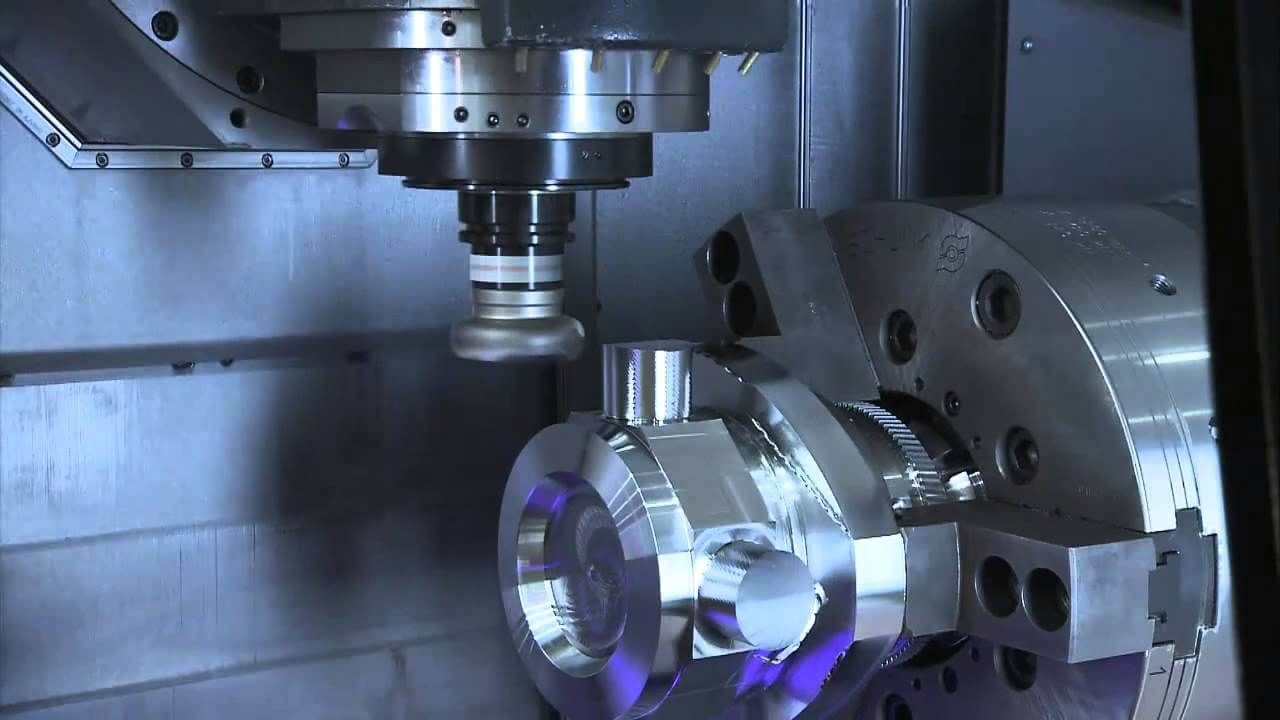

Multi-Axis Machining for Complex Geometries

Multi-axis CNC machines allow for the creation of parts with complex geometries, which are especially important in industries like aerospace and robotics. These machines can manipulate components along multiple axes simultaneously, allowing for more intricate designs and greater flexibility in part production. This capability is crucial for manufacturing components with highly detailed or unconventional shapes, reducing the need for multiple setups and enhancing production efficiency.

Integration of Additive Manufacturing and CNC Machining

The integration of additive manufacturing (3D printing) with CNC machining is another breakthrough that is driving innovation in part production. While additive manufacturing allows for the creation of complex shapes and rapid prototyping, CNC machining ensures that these parts are finished to the highest standards of precision and durability. This hybrid approach is transforming industries by enabling faster production times and reducing material waste, making it an essential tool in modern manufacturing.

Conclusion

CNC machining is a vital technology that continues to shape the aerospace, robotics, and automotive industries in the USA. By providing high precision, efficiency, and adaptability, CNC machining has become indispensable in the production of components for these sectors. As technology advances, the capabilities of CNC machining will continue to evolve, allowing manufacturers to meet the growing demands for lightweight, high-performance, and sustainable solutions. In the ever-competitive landscape of aerospace, robotics, and automotive manufacturing, CNC machining company in usa remains a driving force of innovation.

FAQ

How does CNC machining benefit the aerospace industry?

CNC machining provides the high precision needed for manufacturing critical aerospace components, such as turbine blades and engine parts, ensuring safety, performance, and efficiency in aircraft and spacecraft.

What types of components are produced using CNC machining in robotics?

CNC machining is used to produce precise and durable components like joints, gears, and actuators for robotic arms, as well as custom parts for specialized robotics applications like surgical robots and drones.

How does CNC machining improve the automotive industry’s fuel efficiency?

CNC machining allows for the precise manufacturing of lightweight materials, such as aluminum and carbon fiber, which help reduce vehicle weight and improve fuel efficiency without sacrificing safety or performance.

What is multi-axis CNC machining, and why is it important?

Multi-axis CNC machining enables the production of parts with complex geometries by manipulating components along multiple axes simultaneously. This technology is essential for manufacturing intricate parts used in aerospace and robotics.

How is additive manufacturing integrated with CNC machining?

Additive manufacturing, or 3D printing, allows for the creation of complex shapes, while CNC machining ensures these parts are finish with the necessary precision and durability. This integration streamlines the production process and reduces material waste.