In the ever-evolving world of industrial production, efficiency and productivity are paramount. One key innovation that has significantly impacted industrial operations is the belt conveyor. Used in various industries, from manufacturing and logistics to food processing and packaging, belt conveyors have revolutionized the way materials are moved, processed, and packaged. Their ability to transport goods seamlessly and efficiently has transformed industrial workflows, leading to greater productivity, reduced operational costs, and improved workplace safety. This article will explore how belt conveyors enhance industrial efficiency and productivity.

1. Streamlining Material Handling Processes

Belt conveyors are an essential component in the automation of material handling. These systems allow businesses to move large volumes of products or raw materials with minimal human intervention. By automating the transportation of goods, manufacturers can achieve faster production speeds and reduce the chances of human error. This streamlined process eliminates bottlenecks, decreases downtime, and ensures a smoother workflow, allowing businesses to meet production targets easily.

In many industrial settings, products must be moved through various stages of production. For instance, raw ingredients may need to move from one processing machine to another in a food processing facility. With a belt conveyor, these goods are transported quickly and efficiently, reducing the time spent on manual handling and improving overall throughput.

2. Improved Safety in the Workplace

Another significant advantage of belt conveyors is their ability to enhance workplace safety. Manual labor, such as lifting, carrying, and stacking products, can lead to worker fatigue, injuries, and reduced productivity. Replacing these tasks with a belt conveyor system relieves workers from the physical strain of transporting materials, which helps reduce the risk of workplace accidents.

Additionally, modern conveyor systems are designed with safety features such as emergency stop buttons, adjustable speeds, and guardrails, ensuring that operators are protected from potential hazards. This not only keeps workers safe but also reduces costly accidents and downtime.

3. Increased Production Speed and Efficiency

Belt conveyors play a crucial role in speeding up production lines, especially when paired with automation systems. With their continuous and uninterrupted movement, products are transported quickly between workstations, allowing manufacturing operations to run smoothly without delays. This results in increased production speed, which is critical for businesses looking to maintain a competitive edge.

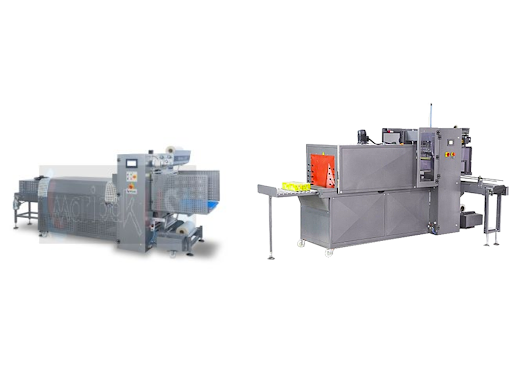

For example, a semi-automatic L sealer machine can work in tandem with a belt conveyor to automatically package products. The belt conveyor feeds products into the sealer, where they are quickly sealed in shrink film. This process is faster and more consistent than manual packaging methods, allowing for higher output levels in a shorter period of time.

4. Flexibility and Customization

One of the key advantages of belt conveyors is their versatility. These systems can be tailored to suit a wide range of industrial applications, with different types of belts, speeds, and designs to accommodate various materials and products. For example, a conveyor can be designed with specialized belts that are ideal for handling fragile products or materials that require extra grip.

Moreover, belt conveyors can be integrated with other equipment, such as a shrink film heat tunnel, to provide a fully automated solution for packaging and processing. In a packaging line, for instance, the belt conveyor moves the product to the shrink film heat tunnel, where it is wrapped and sealed for shipping. This seamless integration of systems results in significant time savings and greater consistency in product quality.

5. Cost Reduction and ROI

Although the initial investment in a belt conveyor system may seem significant, the long-term benefits far outweigh the costs. The increased production speed and efficiency lead to a higher throughput, which translates into greater profitability. Additionally, by reducing the reliance on manual labor and improving workplace safety, businesses can lower operational costs related to staffing and workers’ compensation claims.

Furthermore, a belt conveyor system’s durability and low maintenance requirements help reduce repair and replacement costs over time. This makes it a cost-effective investment that yields a substantial return on investment (ROI) over the life of the system.

6. Optimized Space Utilization

In many industrial settings, maximizing available floor space is a key concern. Belt conveyors are designed to be compact and efficient, allowing businesses to optimize the use of their workspace. Unlike bulky machinery or manual labor stations, conveyor systems can be integrated into existing production lines with minimal disruption.

By utilizing vertical space and routing materials along overhead or inclined conveyors, manufacturers can further optimize their floor layout. This helps create a more organized and efficient production environment, which is essential for increasing productivity.

7. Consistency and Quality Control

With belt conveyors, consistency is key. Unlike manual handling, where inconsistencies can arise due to human error or fatigue, belt conveyors provide a steady and reliable flow of materials. This consistency is crucial for maintaining high-quality standards in production, as each product is handled in the same way, with minimal variation.

In industries such as food processing, pharmaceuticals, and electronics manufacturing, maintaining product quality is essential. Belt conveyors help ensure that materials are transported without damage or contamination, improving product integrity and reducing the likelihood of defects.

8. Easy Integration with Automation Systems

As industries continue to adopt automation, belt conveyors are becoming even more integral to production lines. Conveyor systems can easily be integrated with various automated technologies, such as robotic arms, vision systems, and sorting machines, to enhance efficiency and productivity further. This integration allows for a fully automated production process, where products move seamlessly between workstations without human intervention.

For example, once products are sealed with a semi-automatic L sealer machine, they can be directed to an automated packing station using the same belt conveyor, allowing for continuous, uninterrupted flow from one process to the next.

9. Environmental Benefits

In addition to the operational advantages, belt conveyors can also help businesses achieve sustainability goals. Many modern conveyor systems are designed with energy efficiency in mind, using low-power motors and regenerative drives to reduce electricity consumption. Additionally, by streamlining processes and reducing waste, businesses can lower their environmental impact, contributing to a more sustainable operation.

10. Future-Proofing Your Operations

As industries continue to evolve, investing in belt conveyors ensures that businesses can keep up with future demands. These systems can be easily expanded or modified to accommodate changes in production volumes, product types, or technological advancements. Whether upgrading to faster belts or integrating additional automation, belt conveyors offer the flexibility needed to adapt to the changing landscape of modern manufacturing.

Conclusion

Belt conveyors have revolutionized industrial efficiency and productivity by streamlining material handling, improving safety, increasing production speed, and reducing costs. With their flexibility, ease of integration, and ability to support automation, belt conveyors are a critical component in modern manufacturing and processing systems. Whether used in packaging, food processing, or logistics, these systems are indispensable tools that continue to drive growth and innovation in industries worldwide.