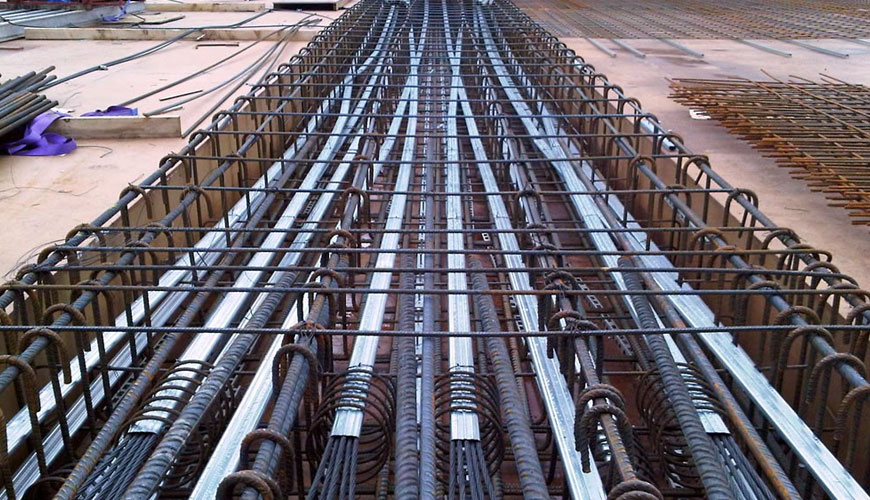

Safety and durability depend mainly on assurance of the integrity of post-tensioned concrete in construction projects. It is attained through post-tensioning, a method of reinforcement for concrete structures, wherein a compressive force is applied to them by tensioning cables or tendons within the concrete after completion or renovation. The tension in such cables usually changes with time, along with certain compromising factors associated with stress, wear, or environmental conditions. Moreover, tension scanning is one of the methods used to measure tension within tendons, allowing engineers to spot any potential problems before they become apparent in performance. This process is crucial for maintaining the strength and stability of post-tensioned concrete so that construction will be safe for a long period.

The top benefits of post-tension scanning in construction projects

Posttension scanning is one of the construction techniques that ensures many benefits in terms of safety and accuracy. A posttension scanner can detect post-tension cables and other underground utilities and cables properly while reducing risks and ensuring effective project management. These are the top benefits of bringing it into construction projects.

- Improved safety of workers and public: Post-tension scanning has great potential to improve safety on site. In projects where post-tensioned concrete is used, cables are stressed to carry heavy loads, and these cables can be concealed in the structure. A post-tension scan can locate the exact position of these cables, preventing their accidental damage during construction activities. In this respect, identifying cables before drilling or cutting reduces the possibility of rupturing cables, which might cause severe accidents, injuries, or even death. Besides, scanning helps ensure workers do not accidentally damage such crucial elements. Accidental damage to post-tension cables results in dangerous situations related to structural failure. Thus, ensuring the safety of the public once the project is completed.

- Improved accuracy in construction works: The major benefits of post-tension scanning include the precision it avails to the construction process. With the precise position of the post-tension cables, the contractors are articulate. They can schedule their activities with a lot of precision, hence reducing errors such as drilling or cutting of cables, which may be costly and hazardous. Results obtained from scanning can also be used to prepare detailed construction drawings to ensure that all works conform to structural design. Besides, correct scanning saves one from errors that might lead to costly reworks or delays. For example, if a construction team can visualise where the cables are precisely located, they can avoid all the complications from dealing with hidden or mislocated cables.

- Prevents structural damage and expensive repairs: Post-tension scanning aims to prevent structural damage that could occur if the post-tension cables are accidentally hit during construction. These cables are essential to the stability of the structure, and their damage could compromise the integrity of the entire building. This can result in expensive repairs, re-stressing of cables, or even replacement sections of the structure, which are all major delays and costs. These can be prevented if scans are made before the activity, which would cause interference to the cables, like drilling and cutting of walls and floors. The post-tension scanning thus enables real-time positioning of cables both vertically and horizontally and enables construction workers to avoid such damages.

- Non-destructive testing and minimal disruption: The advantage of post-tension scanning is that it does not damage the structure. In contrast to the traditional methods, which may require removing sections of concrete or cutting open walls, scanning enables contractors to locate post-tension cables without losing valuable time and money due to unnecessary control actions in construction. The non-destructive nature of the scan negates the need for expensive repairs and downtime associated with destructive testing methodologies. It reduces the risk of creating debris or dust, affecting the work environment and overall project cleanliness. This efficiency is crucial, especially in large projects with limited time and space.

- Compliance with building codes and regulations: Realising building codes and regulations also necessitates post-tension scanning. Many building codes require that locations of post-tension cables be documented for easy examination during and after construction. Scanning ensures that these requirements are met and reduces the likelihood of non-compliance. It is achieved through post-tension scanning, which offers clear and correct data on the exact placement of cables to meet such standards and avoid probable legal issues or penalties that may result from poor construction practices. Additionally, compliance with the building from the beginning may guarantee smoother inspections and faster project approval.

- Facilitates future modifications and renovations: In time, buildings evolve, and owners probably want to alter them by providing new openings for windows, doors, or other utility pathways. The exact presentation of post-tension cables helps contractors avoid modifications that would cause critical element damage by showing accurate positions. Without such information, construction forces might unknowingly damage post-tension cables, which could result in costly replacement parameters. It helps by having a map of the post-tension cables clearly in view for the best planning of renovations, hence making fewer surprises and minimum delays unnecessarily disrupting the proceedings. Moreover, it allows for a future project with no threat of tripping up over hidden cables.

- Enhances long-term structural monitoring: Post-tension scanning may also help monitor a structural condition in the long term. Some buildings are as old as ten and twenty decades old. Therefore, long-term cable changeability should be monitored frequently, which may prove critical in cases such as corrosion, wear, etc. If the above activities are ensured regarding health and safety and good structural status, the building becomes stable and lasts as long as designed. Thus, this helps sustain the service in the structure life period, warding off the undesirable risk of time-consuming and future repairs in years after construction. If recurrent scans are created, then satisfactory data is obtained to assist in keeping secure buildings even past decades after they would have been laid.

Final words

In conclusion, post-tension scanning is crucial in ensuring the safety and integrity of construction projects. Detecting anomalies and confirming the proper placement of tendons helps prevent potential structural failures. Moreover, utilising advanced technology, this method provides accurate, real-time data that allows for informed decision-making. Integrating a reliable post tension scanning solution into construction practices can significantly enhance project quality, mitigate risks, and save costs in the long run. Moreover, it allows for precise detection of stresses and potential issues within concrete elements.