The precision and versatility of CNC machining have revolutionized manufacturing, making it a go-to choice for many industries. Choosing the right CNC machining service, however, can be challenging, given the abundance of providers offering diverse services, capabilities, and costs. This guide will help you identify key factors to consider so you can find a CNC machining partner that aligns with your business needs.

Assess Your Specific CNC Machining Needs

Choosing the right CNC machining service starts with a thorough understanding of your business requirements. Consider the types of parts or products you need, the materials involved, and the required precision levels. Some CNC machining services specialize in specific materials, like metals, plastics, or composites, while others may offer a broader range. Make a list of essential specifications for your products, such as tolerances, dimensions, and finishes, as this will help you determine which service provider is capable of delivering to your standards.

It’s also important to consider production volume. If your business requires large-scale production runs, look for a CNC machining service that can handle high volumes efficiently without compromising on quality. On the other hand, if your needs are limited to prototyping or small-batch production, a provider specializing in low-volume machining may offer more flexibility and lower costs. Being clear about your needs will streamline the selection process, ensuring you find a partner who is well-equipped to meet your specific requirements.

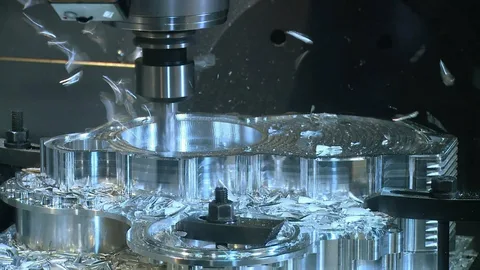

Evaluate the Provider’s Technical Capabilities and Equipment

A critical factor in selecting a CNC machining service is the provider’s technical capabilities. Advanced equipment, such as multi-axis CNC machines, enables more complex and precise machining operations. Ask potential providers about the types of machines they use and the level of precision they can achieve. For example, 5-axis CNC machines allow for intricate geometries that 3-axis machines cannot accomplish. The provider’s equipment should align with the complexity and quality standards of your project.

Furthermore, inquire about the provider’s quality control measures. A reliable CNC machining service will have robust quality assurance procedures in place to ensure consistency and precision. Many providers employ advanced inspection tools like coordinate measuring machines (CMMs) or optical inspection systems. Certification to quality standards, such as ISO 9001 or AS9100, is also an indicator of a company’s commitment to quality. Choosing a provider with strong technical capabilities and proven quality control processes can reduce the risk of costly errors and ensure the final product meets your expectations.

Consider Material Availability and Specialization

Different CNC machining providers may excel in working with specific materials, so it’s essential to find a service that specializes in the materials you require. Some providers might specialize in metals, such as aluminum, stainless steel, or titanium, while others focus on plastics or composites. Confirm that your chosen provider has experience machining your required material, as this affects the quality, durability, and functionality of the final product. Material expertise often translates to better results, as the provider understands how to optimize machining parameters for the material in question.

Material availability is another key consideration, particularly if you need high-quality or specialty materials. Some CNC machining providers maintain in-house stocks of popular materials, which can reduce lead times and ensure faster delivery. Others may rely on third-party suppliers, which could impact turnaround time. Make sure to ask about material sourcing, as a reliable provider should have established relationships with reputable suppliers to ensure consistent quality and availability.

Assess the Provider’s Lead Time, Flexibility, and Scalability

Lead time is a crucial factor in CNC machining, especially if your business operates on tight schedules. Ask potential providers about their standard lead times and inquire whether they offer expedited services for urgent projects. A dependable CNC machining provider will be transparent about their production timelines and any factors that could cause delays. Additionally, consider how quickly the provider can accommodate changes in your project, such as design modifications or order adjustments. Flexibility in production processes can be beneficial for businesses that experience fluctuating demand or require frequent updates to product designs.

Scalability is also vital if you expect to increase your order volume over time. Look for a CNC machining service that can scale its operations to meet your future needs without compromising on quality. Some providers offer contract manufacturing, which can be beneficial if you need a long-term partnership with a supplier capable of handling production growth. Choosing a provider that is both flexible and scalable can save you time and money in the long run, as you won’t need to change suppliers when your production demands evolve.

Review Pricing Structure and Hidden Costs

While cost should not be the sole determining factor, it is essential to understand the pricing structure of your chosen CNC machining provider. Different providers have varying pricing models, including per-unit pricing, hourly rates, or project-based costs. Request detailed quotes from multiple providers to compare prices and evaluate value for money. Pay attention to any additional costs that may not be included in the base quote, such as setup fees, tooling expenses, or post-processing charges. Hidden costs can significantly affect your budget, so ensure you have a complete breakdown of all potential expenses.

Besides pricing, consider the provider’s payment terms and conditions. Some CNC machining services may require upfront payments or deposits, while others might offer payment flexibility based on project milestones or completion. Transparent and favorable payment terms can make a big difference, especially if your business has cash flow considerations. Ultimately, the right CNC machining provider will offer a competitive price without compromising on quality, helping you achieve the desired results within your budget.

Conclusion

Choosing the right CNC machining service is a strategic decision that can impact your product quality, production efficiency, and overall business success. By assessing your specific needs, evaluating the provider’s technical capabilities, and understanding their material expertise, lead times, and pricing structures, you can select a partner who aligns with your business goals. A good CNC machining provider can become a valuable asset, helping you bring your designs to life with precision and reliability.