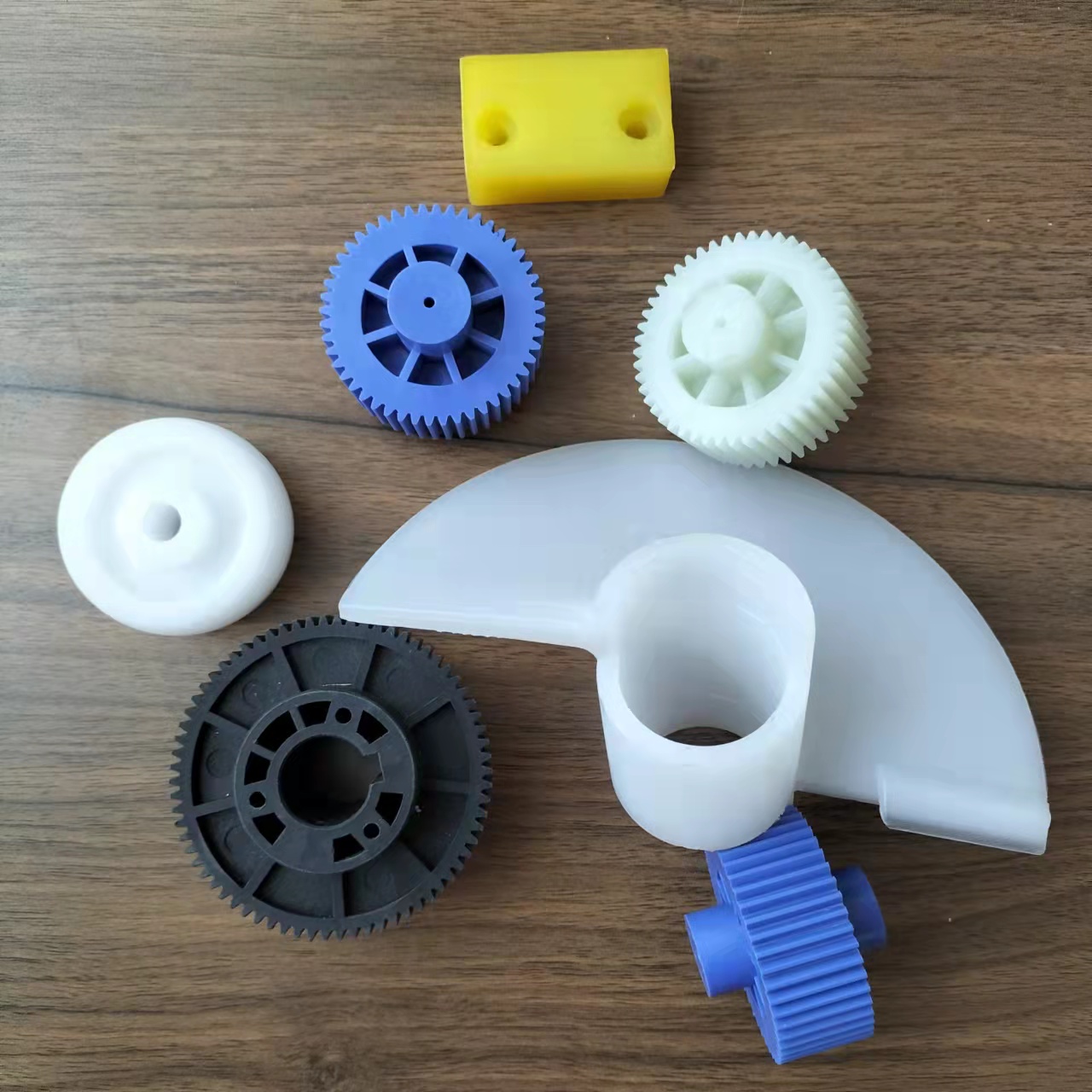

In the world of modern manufacturing, precision and efficiency are paramount. Injection molding stands as one of the most widely used processes for creating high-quality plastic components, catering to industries ranging from automotive to medical. At Petron Thermoplast, we specialize in crafting and supplying top-tier injection molding components that drive precision and reliability in manufacturing operations.

Understanding Injection Molding Components

Injection molding is a complex process that involves various components working seamlessly together to produce parts with exceptional accuracy. Each component plays a critical role in ensuring the efficiency, durability, and quality of the final product. The key injection molding components include:

-

Mold Base

The foundation of the injection molding system, the mold base houses the cavity and core inserts. It provides structural support and ensures the precise alignment of the mold components during the molding process.

-

Cavity and Core

These form the actual shape of the molded part. The cavity represents the exterior, while the core forms the interior details of the component.

-

Clamping Unit

This unit holds the mold securely in place during the injection process, ensuring no leakage or misalignment.

-

Injection Unit

Responsible for melting the plastic resin and injecting it into the mold cavity with high precision and controlled pressure.

-

Ejector System

Once the part cools and solidifies, the ejector system pushes the finished component out of the mold cavity efficiently.

-

Sprue, Runner, and Gate

These channels guide the molten plastic from the injection nozzle into the mold cavity, ensuring uniform distribution.

Applications of Injection Molding Components

Injection molding components from Petron Thermoplast are designed to meet the specific demands of various industries, including:

-

Automotive

- Manufacturing dashboard components, bumpers, and intricate interior parts.

- High-precision parts for engine and transmission systems.

-

Medical and Healthcare

- Production of sterilizable medical devices, syringes, and lab equipment.

- Custom solutions for wearable medical technology.

-

Consumer Goods

- Creation of durable and aesthetically pleasing plastic products for daily use.

- Toys, household items, and electronic device casings.

-

Electronics

- High-quality components for electrical insulation and housing.

- Precision parts for circuit boards and connectors.

-

Packaging

- Lightweight yet robust solutions for food and beverage packaging.

- Custom containers, caps, and closures.

Why Choose Petron Thermoplast for Injection Molding Components?

At Petron Thermoplast, we take pride in delivering superior-quality injection molding components that cater to a diverse range of industrial applications. Here’s why we’re the preferred choice:

-

Precision Engineering

Our advanced manufacturing facilities and experienced team ensure that every component is crafted with unparalleled precision.

-

High-Performance Materials

We use premium-grade materials, including engineering plastics and high-performance thermoplastics, to guarantee durability and reliability.

-

Customization Options

From design to production, we offer customized solutions tailored to your specific manufacturing needs.

-

Stringent Quality Standards

Every component undergoes rigorous testing and quality control to meet international industry standards.

-

Sustainability Focus

We prioritize eco-friendly materials and energy-efficient processes, contributing to sustainable manufacturing practices.

Innovations in Injection Molding at Petron Thermoplast

Our commitment to innovation keeps us at the forefront of the injection molding industry. By leveraging the latest technologies, we ensure:

- Reduced cycle times for faster production.

- Enhanced mold designs for greater efficiency.

- Development of complex and intricate parts with ease.

What is Custom Plastic Injection Molding?

Custom plastic injection molding is a manufacturing process that involves injecting molten plastic into a precisely designed mold to produce a variety of components and products. Unlike standard injection molding, custom molding focuses on creating parts with unique specifications, tailored designs, and precise tolerances to meet specific industry or client requirements.

This process is widely used across industries such as automotive, medical, electronics, and consumer goods due to its ability to produce high-quality parts efficiently and cost-effectively.

How Custom Plastic Injection Molding Enhances Product Design?

In today’s competitive marketplace, innovative product design is a critical factor for success. Businesses need manufacturing solutions that provide precision, efficiency, and flexibility to transform their ideas into reality. Custom plastic injection molding has become a cornerstone of modern manufacturing, empowering businesses to create complex and high-quality products tailored to their specific needs. At Petron Thermoplast, we specialize in offering advanced custom plastic injection molding services that elevate product design and bring visions to life.

Partner with Petron Thermoplast

With a proven track record of delivering high-quality injection molding components, Petron Thermoplast is your trusted partner for precise manufacturing solutions. Our expertise, coupled with a customer-centric approach, ensures that you receive components that enhance your production capabilities and meet your unique requirements.

Contact us today to learn more about our injection molding components and how we can help optimize your manufacturing process. At Petron Thermoplast, precision meets innovation!