Medical wire straightening is an essential process used in various industries, including healthcare, dental, and surgical applications. This technique is crucial for ensuring the accuracy and precision of medical devices that rely on wire components. Whether it’s orthodontic wires, surgical instruments, or medical devices, wire straightening solutions can significantly impact the overall quality and effectiveness of these tools. In this article, we will explore the best medical wire straightening solutions for achieving optimal results, ensuring the success of medical procedures and improving patient care.

Understanding the Importance of Medical Wire Straightening

Medical wire straightening involves the process of transforming coiled or bent wires into a perfectly straight shape, which is essential for many medical applications. Wires that are not adequately straightened may lead to complications during the production of medical devices, potentially affecting the functionality and safety of the devices. Medical wire straightening is used in the creation of a wide range of products, including stents, catheters, orthopedic devices, and orthodontic equipment. The straightening process is critical because wires that are off-center or misaligned can cause malfunction, leading to suboptimal results for patients.

The straightening process itself can be quite complex. Wires made of materials like stainless steel, nitinol, or titanium need to be carefully straightened to maintain their structural integrity while ensuring they meet the necessary specifications. Medical wire straightening solutions are designed to tackle this challenge with advanced technology, delivering high precision, durability, and reliability. Effective straightening solutions can significantly reduce errors, leading to better outcomes for patients and fewer instances of device failure.

Types of Medical Wire Straightening Machines

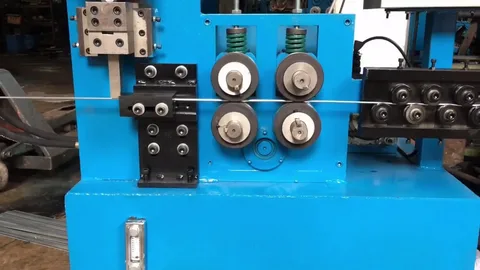

There are various machines and tools used to straighten medical wires, each suited to different wire materials and applications. These machines can range from manual devices to fully automated systems. Manual straightening machines are typically used for smaller batches of wire and are suitable for wire types that do not require high-speed production. These machines allow operators to feed the wire through a set of rollers or guides that exert controlled pressure to straighten the wire.

For larger-scale production or more complex wire materials, fully automated wire straightening machines are often the best solution. These machines are equipped with advanced features like tension control, adjustable rollers, and digital monitoring systems to ensure that each wire is straightened to precise specifications. Automated systems offer higher throughput, which is especially valuable in high-demand environments where large volumes of medical wires need to be processed efficiently. These machines provide consistent results, reduce human error, and improve the overall quality of the wire straightening process.

Key Features to Look for in Medical Wire Straightening Solutions

When selecting the best medical wire straightening solutions, several key features must be considered. One of the most important factors is the level of precision and accuracy the machine can achieve. Since medical wires are often used in life-saving procedures, ensuring that wires are straightened to the correct specifications is critical. Machines that offer fine adjustments and precise control over tension and curvature are preferred for medical wire straightening.

Another critical factor is the compatibility of the straightening solution with different wire materials. Not all wires are created equal, and the characteristics of each material, such as stiffness, flexibility, and strength, can impact the straightening process. The best medical wire straightening solutions are versatile enough to handle various wire types, such as stainless steel, nitinol, and titanium, while maintaining the wire’s integrity. Additionally, machines with built-in features for easy calibration and customization for different wire types can save time and reduce the risk of errors.

Advanced Technologies in Medical Wire Straightening Solutions

Recent advancements in technology have led to the development of more efficient and accurate medical wire straightening solutions. One of the most notable innovations in this field is the integration of robotics and automation. Robotic wire straightening machines can now perform tasks with a high degree of precision and repeatability, reducing the need for manual intervention and the associated risk of human error. These systems are particularly beneficial for applications that require consistent and high-quality results over extended periods.

Additionally, the use of artificial intelligence (AI) and machine learning is beginning to play a role in the development of medical wire straightening solutions. AI-driven systems can analyze data from the wire straightening process to make real-time adjustments and optimize performance. These technologies can predict potential issues, such as inconsistencies in wire tension or alignment, before they occur, leading to faster, more efficient production cycles and minimizing waste. As AI continues to evolve, we can expect even more sophisticated and intelligent medical wire straightening solutions to emerge, further improving the quality and reliability of medical devices.

The Benefits of Investing in High-Quality Medical Wire Straightening Solutions

Investing in high-quality medical wire straightening solutions offers several advantages, particularly in terms of product quality and production efficiency. First and foremost, straightened medical wires are essential for ensuring the functionality and safety of the devices they are used in. Poorly straightened wires can lead to defects in medical devices, which could compromise their effectiveness and endanger patient health. By using top-of-the-line straightening solutions, manufacturers can significantly reduce the risk of device failure and improve patient outcomes.

Another benefit is the increased efficiency in the production process. High-quality straightening machines can operate at higher speeds, which is especially important for manufacturers who need to meet large orders or maintain strict production timelines. These machines can reduce downtime and maintenance costs while delivering consistently accurate results. Moreover, advanced straightening solutions can help streamline the overall production process, allowing manufacturers to scale operations and meet growing demand for medical devices. For businesses in the medical industry, this translates into cost savings, improved customer satisfaction, and a stronger competitive edge.

Conclusion

Medical wire straightening is a crucial step in the production of high-quality medical devices that patients rely on for their health and well-being. The best medical wire straightening solutions are designed to ensure precision, efficiency, and compatibility with a variety of wire materials. Whether through manual or automated machines, the goal is to deliver consistently straight wires that meet the highest industry standards. With advanced technologies like robotics and AI, the future of medical wire straightening looks brighter than ever, offering even more precise and reliable solutions. Investing in these high-quality solutions is a wise decision for any manufacturer looking to enhance the quality of their products and improve patient outcomes.